Family tradition

My grandfather had one metal razor, he had it all his life. Why do I have to keep throwing them away and buying more these days?

Armin Lutz Seidel, developer of the SHAVENT

That's why the SHAVENT flex head razor was created

When an experienced mechanical engineer comes up with an idea while in the shower, something very special can emerge.

August 2019

Annoyed by plastic and rubber on the razor

Wet shaving in the shower is a daily routine for SHAVENT developer Armin. But on this day he has had enough: the blades in the expensive replaceable head are blunt again. He gets so annoyed every time he buys blade cartridges again - about the price, about the unnecessary packaging and about all the waste that is caused by the interchangeable heads.

And what does the thing actually look like? Unattractively calcified and the rubber deposits are already crumbling.

Research

Recalculated and shocked

But how much do you actually spend on these interchangeable heads in such a shaving life? And how much waste does this really create?

Armin researches and is more than surprised: the interchangeable heads of his drugstore razor cost him almost €60 per year. That's thousands of euros for a lifetime of shaving!

Not to mention waste: in Germany alone, so much waste accumulates in just one year that it is equivalent to the weight of the Statue of Liberty in New York - times THIRTEEN! This is crazy!

Classic safety razor

Fixed head & one blade? No comparison.

Switching to grandfather's safety razor didn't solve the problem either. Due to the rigid razor head, you have to ensure the correct angle of the blade on the skin yourself - not a particularly comfortable alternative to the usual flex head. Especially not without a mirror in the shower or for body shaving.

Well, then I develop my own razor.

Prototyping with the 3D printer

Experience meets implementation strength

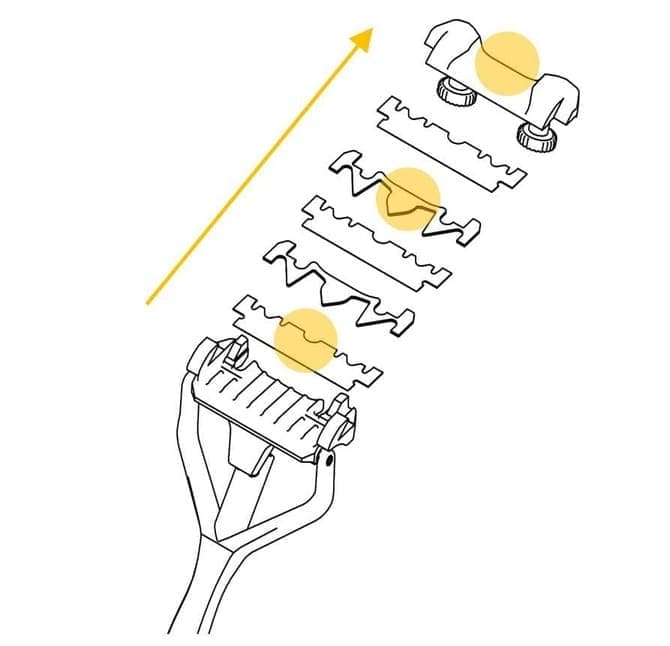

As an experienced mechanical engineer, Armin started with CAD construction. 35 prototypes from the home 3D printer were needed before he could make his vision a reality:

With the SHAVENT, Armin has developed a wet razor that combines all the advantages of a classic razor with the full convenience of modern swing-head razors.

THE SHAVENT

Family business differently

He founded the company together with his daughter Romy

After Armin gave the SHAVENT to his wife Angie and daughter Romy for testing, they too were hooked - because the SHAVENT also proved to be top class for shaving the body.

The decision was clear: father and daughter founded the company behind SHAVENT together as a duo of mechanical engineer and business economist - the spirit of the family business with their initials already built into the company name: Angie Romy Armin turn intoARA.